In today's competitive landscape, production efficiency is more crucial than ever for manufacturing facilities. Companies are constantly seeking ways to improve their processes, reduce waste, and maximize output. This article outlines ten proven strategies that can significantly enhance production efficiency in your operations.

Understanding Production Efficiency

Production efficiency refers to the ability of a manufacturing facility to produce goods with minimal waste and maximum output. It encompasses various factors, including resource management, workflow optimization, and employee productivity. But how can you achieve this elusive goal?

1. Implement Lean Manufacturing Principles

Lean manufacturing focuses on minimizing waste while maximizing productivity. By adopting lean principles, you can streamline processes and eliminate unnecessary steps. This approach not only enhances production efficiency but also improves overall quality.

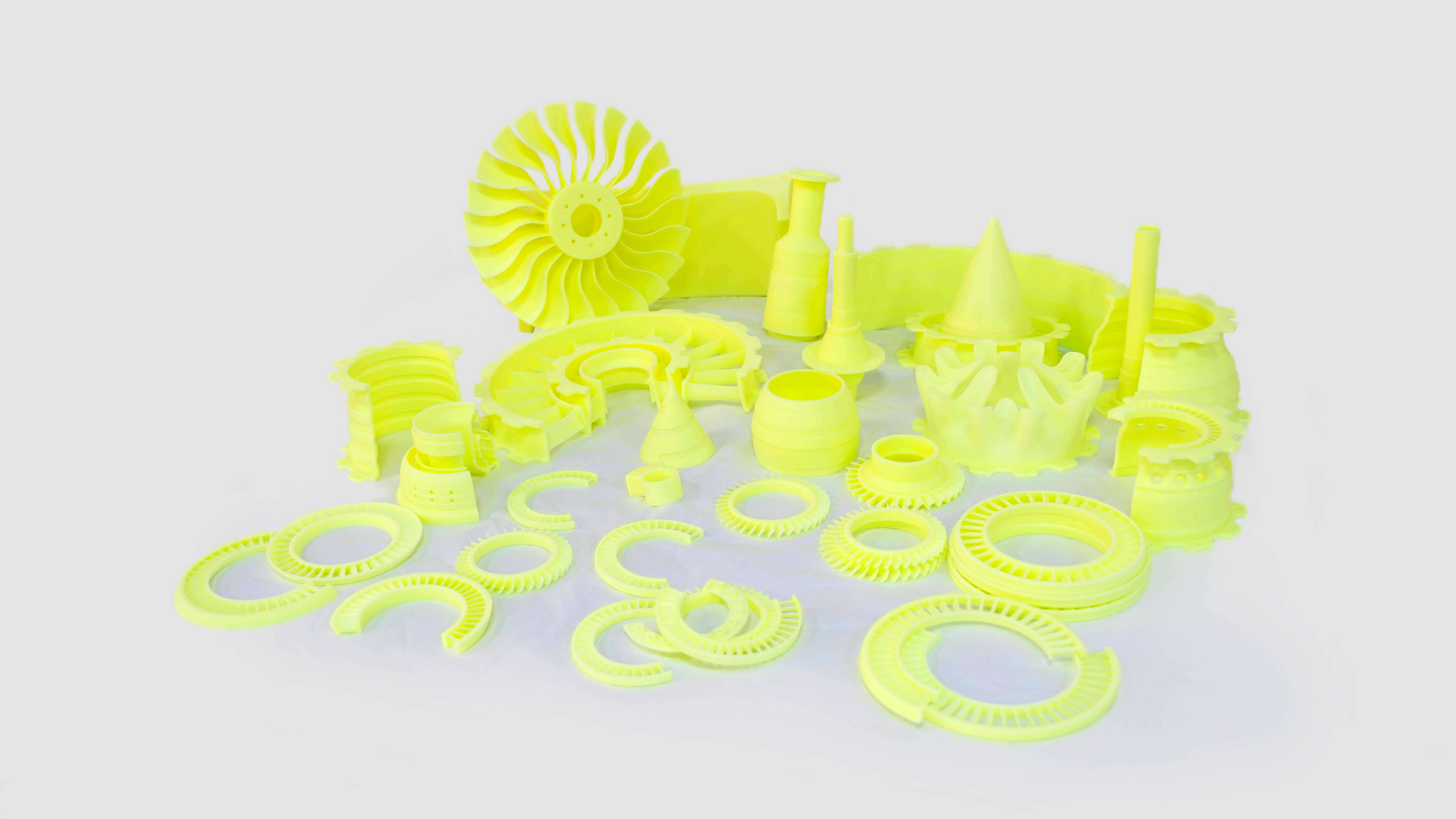

2. Invest in Technology

Modern technology plays a pivotal role in enhancing production efficiency. Automation tools, such as robotics and AI-driven systems, can significantly reduce manual labor and increase precision. For instance, the use of 3D printing technology allows for rapid prototyping and reduced lead times, leading to a more efficient production cycle.

"Investing in technology is not just an option; it is a necessity for staying competitive in the manufacturing sector."

3. Optimize Supply Chain Management

Effective supply chain management is vital for maintaining production efficiency. By optimizing inventory levels and improving supplier relationships, you can ensure that materials are available when needed, reducing downtime and enhancing workflow.

4. Foster a Culture of Continuous Improvement

Encouraging employees to contribute ideas for process improvements can lead to significant gains in production efficiency. Implementing regular training sessions and feedback loops can empower your workforce to identify inefficiencies and suggest solutions.

Key Strategies for Enhancing Production Efficiency

5. Monitor Key Performance Indicators (KPIs)

Tracking KPIs related to production efficiency can provide valuable insights into your operations. Metrics such as cycle time, defect rates, and overall equipment effectiveness (OEE) can help identify areas for improvement.

6. Utilize Data Analytics

Data analytics can reveal patterns and trends that may not be immediately apparent. By analyzing production data, you can make informed decisions that enhance efficiency and reduce costs.

7. Standardize Processes

Standardizing processes ensures consistency and quality in production. By creating clear guidelines and protocols, you can minimize errors and streamline operations, ultimately boosting production efficiency.

8. Enhance Workplace Safety

A safe working environment is essential for maintaining productivity. By prioritizing safety measures, you can reduce accidents and downtime, leading to improved efficiency.

9. Engage in Regular Maintenance

Regular maintenance of equipment is crucial for preventing breakdowns and ensuring optimal performance. Implementing a proactive maintenance schedule can significantly enhance production efficiency.

10. Evaluate and Adapt

Finally, it is essential to regularly evaluate your production processes and adapt as necessary. The manufacturing landscape is constantly evolving, and staying flexible can help you maintain high levels of production efficiency.

Conclusion

Enhancing production efficiency in your manufacturing facility is a multifaceted endeavor that requires commitment and strategic planning. By implementing these ten proven strategies, you can create a more efficient, productive, and profitable operation.

References